Industrial valves are critical across oil & gas, chemicals, power, water, and general manufacturing. They control, isolate, and protect the flow of liquids, gases, slurries, and semi-solids under a wide range of pressures and temperatures. Equip Up sources industrial valves in multiple sizes, pressure classes, and materials to match your media, standards, and plant conditions. Whether you’re replacing a single valve or supporting a full project, we connect you with trusted OEMs and quality-approved manufacturers.

Ball Valves

Ball valves provide quick, quarter-turn on/off control for liquids and gases. Available in one-piece, two-piece, and three-piece designs, with flanged, threaded, or welded ends, they offer tight shutoff and long service life. Equip Up supplies industrial ball valves in carbon steel, stainless, and alloy materials for a wide range of pressures, temperatures, and process media.

Gate Valves (Sluice Valves)

Gate valves are one of the most widely used isolation valves in pipelines. They are designed to be either fully open or fully closed, not for fine throttling.

We source screwed, union, bolted-bonnet, welded-bonnet, and pressure-seal gate valves in various sizes and ratings for oil & gas, water, and process applications.

Butterfly Valves

Butterfly valves use a rotating disc to control flow and are ideal where space and weight are a concern. They’re widely used in water distribution, HVAC, chemicals, agriculture, and plant services.

Equip Up procures wafer, lug, and flanged butterfly valves with different seat and disc materials to match your pressure, temperature, and corrosion requirements.

Globe Valves

Globe valves offer good throttling and shutoff capability, making them suitable for flow control applications. Typical uses include cooling water systems, fuel oil lines, turbine seals, and vents.

We supply globe valves in a range of sizes, trims, and pressure classes to support precise control in process and utility services.

Plug Valves

Plug valves are quarter-turn valves used for fast, reliable shutoff and directional control. They handle liquids and gases under demanding conditions and are common in petroleum pipelines and chemical processing. Equip Up sources lubricated and non-lubricated plug valves designed to handle high temperatures, abrasive media, and corrosive fluids.

Check Valves

Check valves allow flow in one direction and prevent reverse flow that could damage equipment or disrupt processes. They are used with liquids, gases, steam, condensate, and slurries. We procure swing, lift, piston, and non-slam check valves, sized and specified for your line conditions and media.

Needle Valves

Needle valves enable precise, gradual adjustment of flow, typically in small lines and instrumentation applications. They’re used for steam, oil, gas, air, and vacuum systems where accurate control at low flow rates is critical. Equip Up supplies needle valves in various pressure ratings and materials for instrumentation, sampling, and fine control duties.

Actuated Control Valves

Actuated control valves regulate flow automatically based on process signals, handling everything from corrosive chemicals to high-pressure steam. They are essential in power generation, refining, chemical plants, and transmission systems.

We source valve bodies, actuators (pneumatic, electric, hydraulic), positioners, and accessories as complete control valve packages built to your control philosophy and standards.

Solenoid Valves

Solenoid valves use an electrical coil to open or close the valve, providing fast, automatic control of fluids and gases. They are used in heating systems, compressed air lines, automation, water treatment, and more.

Equip Up provides solenoid valves in different voltages, body materials, and port configurations for industrial and commercial applications.

Safety / Relief Valves

Safety (relief) valves protect equipment and systems from overpressure by venting when set pressure is exceeded. They are often the last line of defense in chemical plants, gas storage, boilers, and pressure vessels. We source safety and relief valves compliant with relevant codes and standards, sized and set according to your process and design conditions.

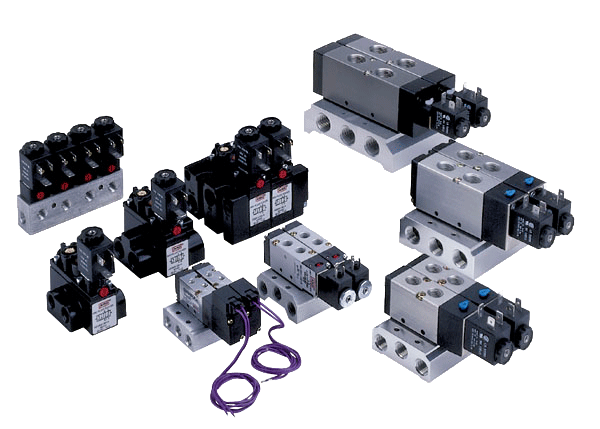

Pneumatic Valves

Pneumatic valves control compressed air for actuators and tools, managing pressure, flow, and direction in pneumatic systems. Equip Up supplies pressure regulators, directional control valves, and flow control valves for a broad range of industrial automation and actuation systems.

Pinch Valves

Pinch valves are ideal for abrasive, corrosive, or slurry service. A flexible sleeve is “pinched” to stop or control flow, providing straight-through, full-bore flow when open.

We procure pinch valves designed for mining, wastewater, chemical slurries, and other harsh services where traditional valves wear quickly.

Diaphragm Valves

Diaphragm valves use a flexible diaphragm to control flow, offering clean, low-dead-leg design and reliable shutoff. They are well suited for throttling and on/off service in hygienic, corrosive, or slurry applications. Equip Up sources weir-type and straight-through diaphragm valves for water treatment, pharmaceuticals, food & beverage, and chemical processes.

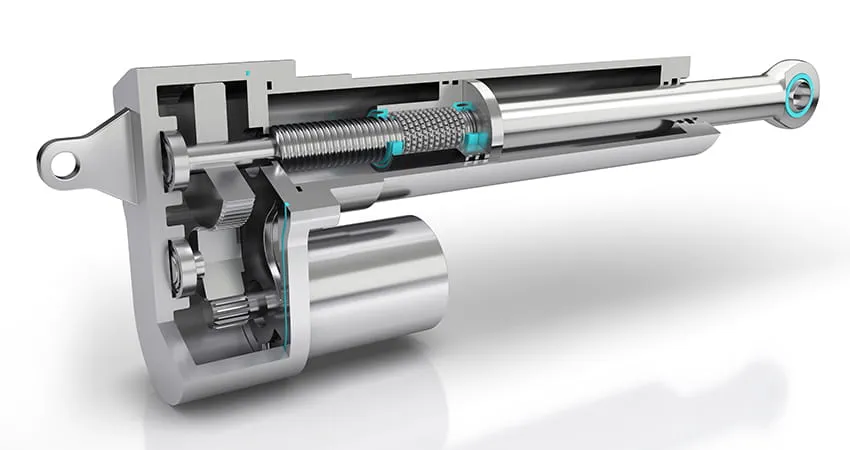

Electric Actuators

Electric actuators provide precise, programmable valve actuation without hydraulic power packs or air systems. They improve accuracy, repeatability, and control while simplifying infrastructure.

We supply electric actuators for quarter-turn and multi-turn valves, specified to your torque, speed, control, and environmental requirements.

Flanges

Flanges connect valves, piping, and equipment and must meet strict dimensional and material standards. Equip Up sources welding neck, slip-on, socket weld, lap joint, threaded, and blind flanges in carbon steel, stainless steel, alloy, and other materials, compliant with major international standards.

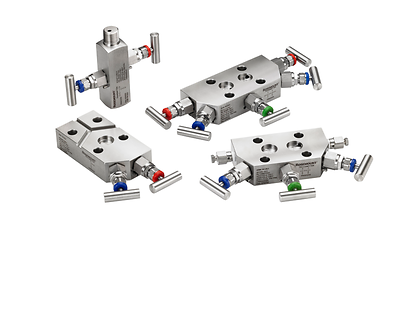

Manifolds

Manifolds combine or distribute flow between multiple lines, widely used in instrumentation, hydraulic, and process systems.

We procure a variety of manifold types and configurations, specified by pressure rating, temperature, material, number of ports, and valve style, so your system is compact, safe, and easy to maintain.