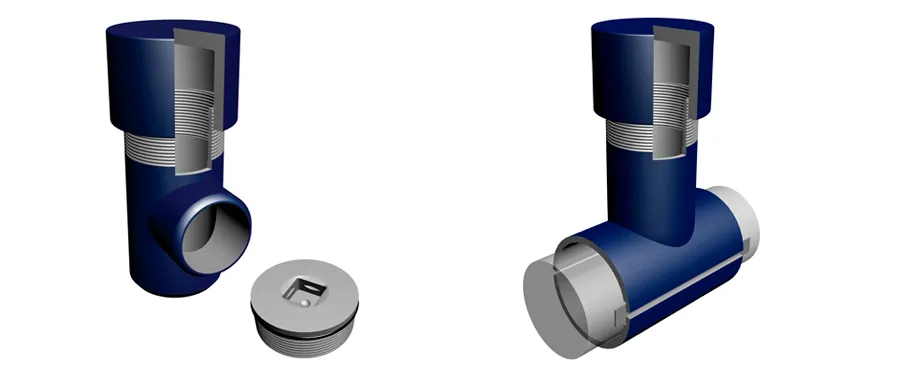

Threaded Plug Linestop Fittings (Distribution)

The THREADED FITTINGS are designed for main relocations, lateral connections, line extensions, equipment tie-ins, linestop operations. They are also used for purge & equalization operations. The flat bottom THREADED FITTING includes a threaded internal plug, an O-ring, a threaded external cap and a flat bottom nipple. They are available in sizes 1-1/4”, 1-1/2”, 2”, 3” and in Class 150, 300. According to the size of the main pipeline, the THREADED FITTING needs an additional reinforcement like a: Weldolet or Pad. The reinforcement is according to the client’s specifications. If the THREADED FITTING has the same size than the main pipeline (size-on-size), the THREADED FITTING needs a full encirclement reinforcement. In case there is no reinforcement needed, TECPESA also manufactures this fitting with a scarfed or flat bottom ending.

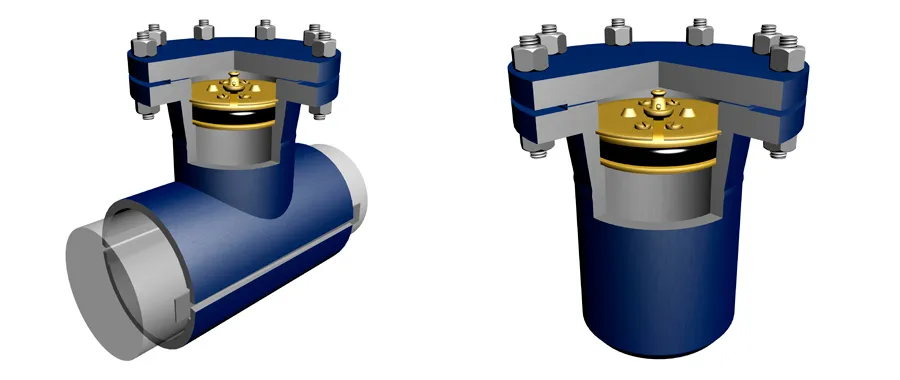

Completion Plug Linestop Fittings

The COMPLETION PLUG FITTINGS are designed for main relocations, lateral connections, line extensions, equipment tie-ins, linestop operations all without shutdown. They are used also for gas bag installations. The COMPLETION FITTINGS are furnished with a blind flange with studs, nuts, gasket, an internal completion plug with an O-ring and a flat bottom flanged nipple. They are available in sizes 4”, 6”, 8”, 10”, 12” and in Class 150 and 300. With a flange class 150, the maximum operating pressure is 19 bar. With a flange class 300, the maximum operating pressure is 51 bar. According to the size of the main pipeline, the completion plug fitting needs an additional reinforcement like a: Weldolet or Pad. If the completion fitting has the same size than the main pipeline (size-on-size), needs a full encirclement reinforcement. The reinforcement is according to the client’s specification. In case there is no reinforcement needed, TECPESA also manufactures this fitting with a scarfed or flat bottom ending. The COMPLETION PLUG FITTINGS are also available with a reducing branch to be used as bypass fittings or to connect different pipeline sizes.

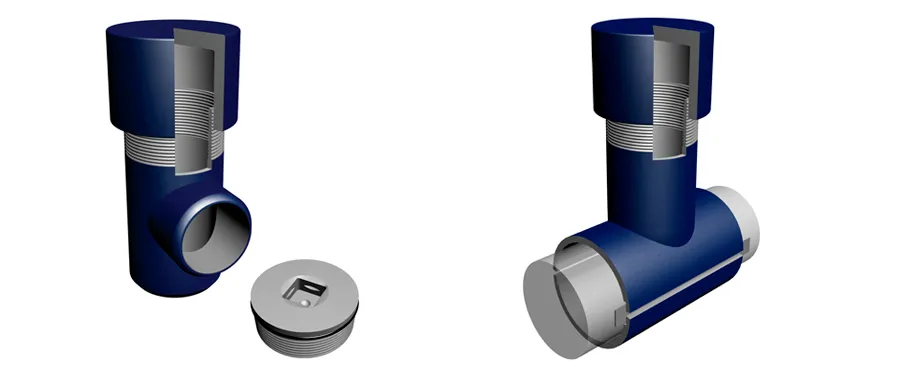

Threaded Plug 3 Way Tee Fittings

The THREADED 3 WAY TEE fittings are designed for main relocations, lateral connections, line extensions, equipment tie-ins, linestop operations, all without shutdown. The THREADED 3 WAY TEE fitting includes a threaded internal plug with O-ring, an external cap and a flat bottom nipple. They are available in sizes 1-1/4”, 1-1/2”, 2”, 3” and in Class 150, 300. They allow to plug in different directions. According to the size of the main pipe, the THREADED 3 WAY TEE fittings need an additional reinforcement like a: Weldolet or Pad. The reinforcement is according to the client’s specifications. If the THREADED 3 WAY TEE fitting has the same size than the main pipeline (size-on-size), the threaded 3 way fitting needs a full encirclement reinforcement (right). In case there is no reinforcement needed, TECPESA also manufactures this fitting with a scarfed or flat bottom ending.

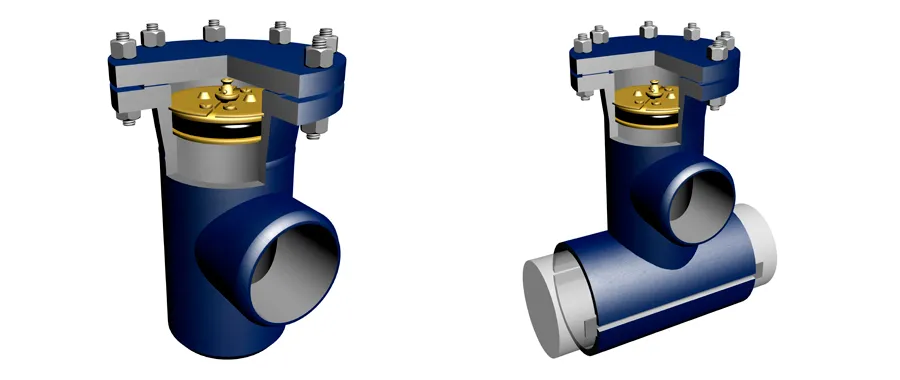

Completion Plug 3 way tee fittings

The COMPLETION PLUG 3 WAY TEE fittings are designed for main relocations, lateral connections, line extensions, equipment tie-ins, linestop operations, all without shutdown. The COMPLETION PLUG 3 WAY TEE fittings are furnished with a blind flange with studs, nuts and gasket, an internal completion plug with O-ring and a flat bottom flanged nipple. They are available in sizes 4”, 6”, 8”, 10”, 12” Class 150 and Class 300. With a flange Class 150, the maximum operating pressure is 19 bar. With a flange class 300, the maximum operating pressure is 51 bar. They allow to plug in different directions. According to the size of the main pipe, the COMPLETION PLUG 3 WAY TEE fittings need an additional reinforcement like a: Weldolet or Pad. The reinforcement is according to the client’s specifications. When the COMPLETION PLUG 3 WAY TEE fitting has the same size than the main pipeline (size-on-size), the completion 3 way tee fitting needs a full encirclement reinforcement. In case there is no reinforcement needed, TECPESA also manufactures this fitting with a scarfed or flat bottom ending. The COMPLETION PLUG 3 WAY TEES are also available with a reducing branch to be used as bypass fittings or to connect different pipeline sizes.

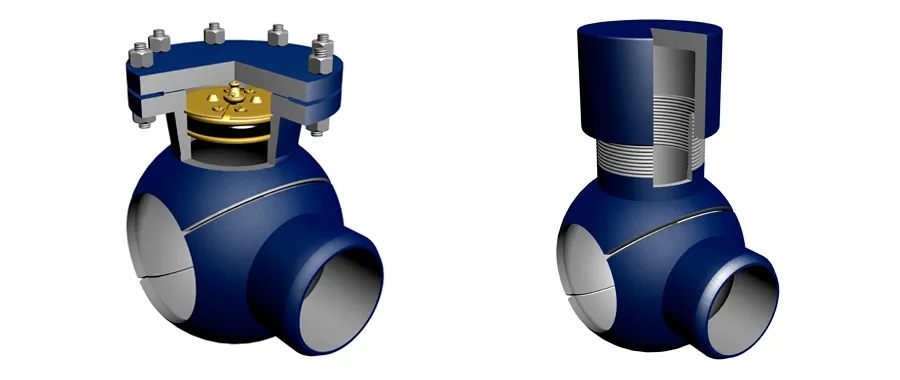

Threaded & Completion Plug Spherical 3 Way Tee

The THREADED & COMPLETION SPHERICAL 3 WAY TEES are designed for main relocations, lateral connections, line extensions, equipment tie-ins, linestop operations; all without shut down the line. The 2″-3″ THREADED SPHERICAL 3 WAY TEE is furnished with a threaded nipple, a threaded internal plug with O-ring and an external threaded cap, all welded to a full branch sphere. It is available in Class 150 and 300. The COMPLETION SPHERICAL 3 WAY TEE is furnished with a grooved flange to engage the leaves of standard completion plug, a blind flange with bolts, nuts and gasket, an internal completion plug with Oring – all welded to a full branch sphere. It is available in sizes 4″, 6″, 8″, 10″, 12″ and in class 150 and 300. With a flange Class 150, the maximum operating pressure is 19 bar. With a flange Class 300, the maximum operating pressure is 51 bars. The bottom half of the SPHERICAL 3 WAY TEE can be turned to a side or a bottom outlet. The tee can also be installed horizontally.