Enhance Pipeline Control with a Powerful Line Stop Machine Solution

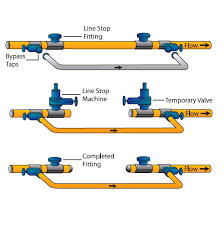

Understanding the Purpose of a Line Stop Machine In our operations, we rely heavily on the line stop machine to manage and maintain active pipelines without halting the flow. This machine allows us to isolate sections of a pipeline while keeping the rest in service. It’s perfect for planned repairs, maintenance, or modifications. We position the machine strategically and use advanced hydraulic technology to perform safe interventions. With growing infrastructure complexity, this tool is critical. Our team is trained and equipped to operate the line stop machine in high-pressure environments while ensuring minimal disruption. It’s a core solution in our line isolation strategy. Precision Engineering with Our Line Stop Fitting A successful pipeline intervention depends greatly on the quality of the line stop fitting. These fittings form a secure and pressure-rated connection that holds the line stop equipment in place. At Equip Up, we source and install the highest-grade fittings that can withstand the required pressure ratings and match pipeline specifications. The line stop fitting is welded or mechanically attached and becomes part of the pipeline during and after the procedure. We ensure every fitting is pressure-tested and corrosion-resistant. Proper fittings ensure the integrity and safety of the entire system during line stopping. Streamlined Operations Through Hot Tap Line Stop Technique When downtime is not an option, we implement the hot tap line stop method to gain access to pressurized pipelines. This process combines hot tapping and line stopping to avoid complete system shutdown. First, we perform a hot tap to install the fitting; then, we introduce the line stop equipment. The hot tap line stop is an industry-standard approach that allows us to complete maintenance safely and efficiently. It’s ideal for systems carrying gas, water, or oil. Our team conducts rigorous safety checks, making the process secure and seamless for all industries we serve. Reliable Services for All Line Stopping Requirements Line stopping is our core specialty. We deliver turnkey solutions for commercial, municipal, and industrial pipelines that require controlled intervention. From planning to execution, our crew handles every step with precision. Our tools and methods are built for reliability and compliance. Whether it’s emergency shutdowns or planned upgrades, our line stopping service ensures continuity and safety. We also document every detail, from isolation points to pressure data. This level of accuracy and professionalism is what sets our team apart. When you need effective pipeline control without service interruption, our line stopping experts are your first choice. What is a Line Stop in Piping? A line stop in piping is a temporary method used to isolate a section of a pipeline without shutting down the entire system. It allows maintenance, repairs, or modifications to be carried out on part of the system while the rest continues to operate normally. This technique is often used in industrial plants, water systems, and gas pipelines where full system shutdowns are costly or impractical.Key points about line stops: 🔧 Temporary Isolation: Used to block off flow in a pipeline temporarily.🚫 Non-shutdown Solution: Enables work on a live system without a full shutdown.⚙️ Used with Hot Taps: Often installed after a hot tap connection has been made.🔄 Removable Equipment: The stop can be removed once work is complete and normal flow can resume.🛠️ Common in Maintenance: Useful for valve replacements, tie-ins, and rerouting without disrupting service. Line stopping is a critical method in pipeline management for minimizing downtime and maintaining operational efficiency. Safety Benefits of Using a Line Stop Machine We always prioritize safety, and the line stop machine offers major advantages in this area. By avoiding full system shutdowns, we reduce the risks of pressure surges and system restarts. The machine is designed with high-strength materials, reliable seals, and precise pressure control. These features allow us to stop flow without compromising the system’s integrity. We also follow detailed procedures for testing, calibration, and safety assessments before and after every job. The line stop machine improves both operational and environmental safety. Our crew is trained to respond quickly and act with confidence under pressure. Designing Custom Solutions with the Right Line Stop Fitting No two pipelines are alike, and we tailor each line stop fitting to match project requirements. We take into account pressure class, pipe diameter, material, and operating conditions. Our in-house fabrication team works closely with engineers to produce fittings that perform under the harshest conditions. Every line stop fitting is certified and traceable, giving our clients peace of mind. Whether we use temporary or permanent solutions, the end result is always durable and reliable. We believe in quality materials, expert welding, and smart design to ensure that each line stop works exactly as it should. Saving Time and Money with a Hot Tap Line Stop Every project has a budget and deadline. Our hot tap line stop services help reduce both cost and downtime. Traditional shutdowns require draining, purging, and restarting systems, which costs time and money. With our method, we bypass all of that. This service is ideal for emergency work, tie-ins, or adding new lines to a live system. We’ve used the hot tap line stop process on everything from small water mains to high-pressure steam pipelines. By choosing this method, our clients maintain production while completing necessary upgrades or fixes with minimal impact. Field-Proven Techniques in Every Line Stopping Project We approach each line stopping project with a proven methodology. First, we conduct a detailed site assessment, followed by equipment setup, safety checks, and execution. Our skilled technicians use hydraulic rams, plugging heads, and reinforced housings to achieve a secure block. We also offer double line stops for zero-flow conditions. Our documentation includes step-by-step breakdowns, which ensures future serviceability and compliance. We train continuously to improve technique and safety. With every line stopping job, we uphold our reputation for quality, efficiency, and reliability. Clients trust us for critical system work with minimal disruption. Why Equip Up Is Your Best Partner for Line Stopping Needs At Equip Up, we bring decades of experience and innovation to every pipeline

Enhance Pipeline Control with a Powerful Line Stop Machine Solution Read More »