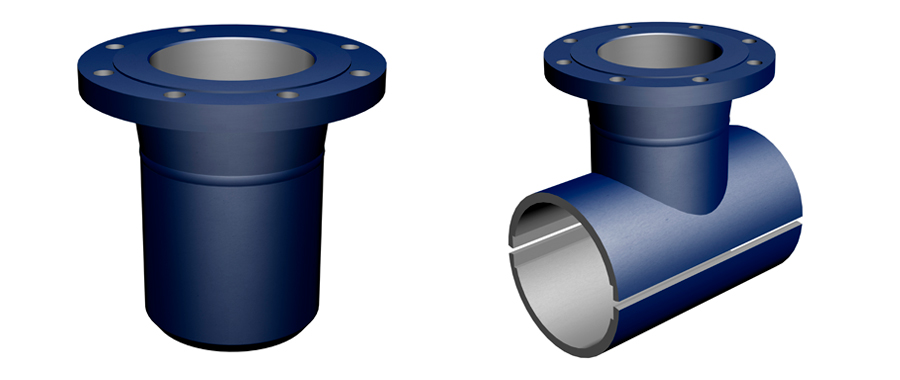

A 3 way tee completion plug is a fitting used in plumbing and piping systems. It is designed to close off or seal one of the outlets of a three-way tee fitting. This plug is usually threaded and can be easily inserted into the open outlet of the tee to block the flow of fluid or gas through that particular branch of the piping system. These Tecpesa Completion Plug 3 way tee fittings are commonly used during maintenance, repairs, or pipeline system modifications when one branch of the tee needs to be isolated or sealed off temporarily. They come in various materials, such as metal and stainless steel, suit different applications and are available in different sizes ( 4”, 6”, 8”, 10” and 12” to match the dimensions of the tee fitting they are intended for. When selecting a Completion Plug 3 way tee fittings, it is essential to consider the material compatibility with the piping system and the pressure class (150# / 19 bar and 300# / 51 bar and temperature ratings to ensure safe and effective sealing of the tee outlet. What are the Different Kinds of 3 Way Tee Fitting There are several types of 3 way tee fittings available, especially when it comes to tee completion plugs. Each of them are designed for specific applications and requirements. Some common types include: Threaded Plug Linestop Fittings (Transmission) The THREADED FITTINGS are designed for main relocations, lateral connections, line extensions, equipment tie-ins, linestop operations. They are also used for purge & equalization operations. The flat bottom THREADED FITTING includes a threaded internal plug, an O-ring, a threaded external cap and a flat bottom nipple. They are available in sizes 1-1/4”, 1-1/2”, 2”, 3” and in Class 600, 900. According to the size of the main pipeline, the THREADED FITTING needs an additional reinforcement like a: Weldolet or Pad. The reinforcement is according to the client’s specifications. Autoblock Plug 3 Way Tee Fittings The AUTOBLOCK PLUG 3 WAY TEES fittings are full branch 3 way tees designed for main relocations, lateral connections, line extensions, equipment tie-ins, linestop operations, all without shutdown. The AUTOBLOCK 3 WAY TEE fittings are furnished with a drilled and faced autoblock flange, a blind flange with studs, nuts and gaskets, an internal high pressure plug (autoblock plug) with O-ring and a tee. They are available in sizes from 4” to larger sizes, Class 300, 600 and 900. Autoblock Plug Spherical 3 Way Tee The AUTOBLOCK PLUG SPHERICAL 3 WAY TEES are designed for main relocations, lateral connections, line extensions, equipment tie-ins, linestop operations; all without shutdown the line. The AUTOBLOCK PLUG SPHERICAL 3 WAY TEE is furnished with a drilled and faced autoblock flange, blind flange with bolts, nuts and gasket, an internal autoblock plug (high pressure plug) with O-ring, all welded to a full branch sphere. It is available in sizes from 4” in Class 300, 600 and 900. In any case, the maximum installation pressure is the maximum operating pressure of the Equipment. The bottom half of the SPHERICAL 3 WAY TEE can be turned to a side or a bottom outlet. The tee can also be installed horizontally. What is a Spherical 3 Way Tee Completion Plug? A spherical 3 way tee completion plug is a specialized type of completion plug designed specifically for sealing off one of the outlets of a three-way tee fitting. Unlike traditional plugs that have a flat or tapered design, spherical plugs have a spherical or ball-shaped end, which allows for a more uniform distribution of pressure against the inner walls of the tee outlet when inserted.The spherical shape of these plugs ensures a secure and leak-proof seal, even in applications where there may be slight misalignment or irregularities in the tee outlet. This makes them particularly useful in systems where a high degree of sealing integrity is required. These plugs are made from durable materials such as metal or high-performance plastics to withstand the pressures and temperatures commonly encountered in plumbing and piping systems. They are available in various sizes to match the dimensions of different three-way tee fittings and can be threaded, compression, or push-fit depending on the specific requirements of the application. If you are looking for a 3 way tee completion plug, visit Equip Up and shop from our Tecpesa branded variety of 3 way fittings. Visit us today and explore our range of 3-way completion plugs and other fittings for your piping project. We can deliver fittings, equipment and offer hot taping or stopple service in any location globally.